Shreeniwas Equipment is a leading wiring harness manufacturers, suppliers, exporters in

India. We are offering the best quality of wiring harness and are committed towards offering

the most suitable solutions that make and enhance electrical connections in industries.

We have the experience of manufacturing customized wiring harness with the benefit of

precision and reliability that allows us to offer it to the automotive sector as well as

local markets before competition. Following are its different types, new technological

aspects of, its advantages of use and applications as well!

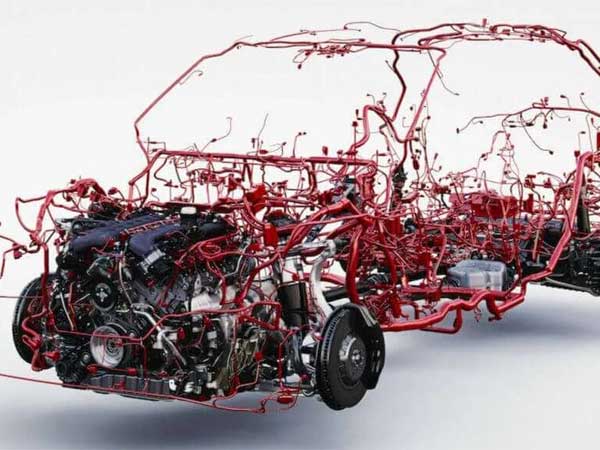

What Is a Wiring Harness and Why It Matters?

A wiring harness is an organized assembly of wires, connectors, and terminals that transmits electrical power and signals in a system. It simplifies electrical design by bundling multiple cables into a single unit, reducing clutter and installation time. Wiring harnesses are crucial for reliability, safety, and efficient maintenance in vehicles, machinery, and electronic devices.

Types of our Wiring Harness

Being the best wiring harness in India, we are providing the best quality of wiring

harness such as:

1. EV Cluster Wiring Harness

EV Cluster Wiring Harness connects dashboard display components and electronic systems in electric vehicles. It enables seamless communication between battery, motor, and digital instruments. Designed for high efficiency and safety in electric vehicle environments.

Get more info about EV Wiring harness at Wiring Harness for Elecric Vehicles

- Advantages: Reliable signal transmission, compact design, reduced wiring errors

- Features: High-voltage insulation, CAN bus compatibility, flame retardant coating

- Benefits: Enhanced EV performance, simplified assembly, improved driving safety

2. LED Display Wiring Harness

This harness is used to power and control LED displays in digital signage and electronic boards. It ensures synchronized lighting and steady electrical supply. Ideal for indoor and outdoor LED applications.

- Advantages: Stable power flow, precise signal transfer, long lifespan

- Features: Plug-and-play connectors, moisture resistance, multi-pin configuration

- Benefits: Bright and clear display, quick installation, minimal maintenance

3. Home Appliances Wire Harness

Home appliances wire harnesses connect internal electrical components in devices like refrigerators, washing machines, and microwaves. They ensure safe current flow and device reliability. Built to match household voltage standards.

- Advantages: Cost-effective, reliable, customizable for appliance type

- Features: Heat-resistant sheathing, standardized connectors, compact layout

- Benefits: Better appliance performance, user safety, fewer breakdowns

4. Electrical Wiring Harness

General-purpose electrical wiring harnesses are used across various industrial and residential applications. They organize and protect wires within electrical systems. Suitable for both high and low-voltage setups.

- Advantages: Simplifies wiring systems, improves safety, reduces installation time

- Features: Insulated wires, durable terminals, bundled cable arrangement

- Benefits: Efficient power distribution, lower risk of short-circuits, easy diagnostics

5. Earth Equipments Wiring Harnesses

These harnesses are designed for heavy-duty earth-moving equipment like excavators and bulldozers. They handle high vibrations and extreme environmental conditions. Built for rugged, outdoor use.

- Advantages: Withstands harsh environments, corrosion-resistant, high flexibility

- Features: Weatherproof jackets, vibration-proof clips, heavy-gauge wiring

- Benefits: Reliable field performance, reduced downtime, lower maintenance cost

6. Heavy Vehicles Wiring Harness

Used in buses, trucks, and construction vehicles, this harness manages complex electrical systems. It connects lighting, sensors, brakes, and control units. Essential for vehicle safety and operation.

- Advantages: Robust design, high current handling, temperature-resistant

- Features: Shielded cables, secured connectors, modular build

- Benefits: Stable system control, easy upgrades, increased vehicle lifespan

7. Automotive Wire Harness

Automotive wire harnesses integrate all electrical components in a car including lighting, engine, sensors, and entertainment systems. Designed for reliability and performance under dynamic conditions.

- Advantages: Space-saving, durable, vibration-resistant

- Features: Color-coded wires, protective sleeving, OEM-specific design

- Benefits: Safer driving experience, efficient repairs, enhanced fuel efficiency

8. Engine Wiring Harness

Engine wiring harnesses connect the engine’s electronic components like sensors, ignition, and fuel injectors. They ensure precise engine control and diagnostics. Built for high-temperature zones.

- Advantages: Heat-resistant, optimized for fuel systems, secure fitting

- Features: Braided shielding, reinforced connectors, thermal sleeves

- Benefits: Smoother engine performance, reduced fault risks, improved fuel management

9. Tractor Wiring Harness

Tractor wiring harnesses support the electrical systems of agricultural tractors. They handle lighting, ignition, sensors, and auxiliary equipment. Engineered for outdoor durability and long hours of operation.

- Advantages: Weatherproof, strong mechanical protection, load-bearing capacity

- Features: Waterproof joints, abrasion-resistant coating, multi-branch layout

- Benefits: Continuous operation in fields, minimal downtime, farmer safety

10. Motor Wiring Harness

This harness connects electric motors to power supplies and control panels in various machines. It supports accurate motor function and speed regulation. Common in industrial machinery and HVAC systems.

- Advantages: Efficient power flow, signal integrity, compact assembly

- Features: Tinned copper wires, thermal insulation, EMI shielding

- Benefits: Improved motor efficiency, reduced noise, reliable system operation

Technical Specifications

We have mentioned below a technical sheet table of Wiring Harness for more understanding such as:

| Specification |

Details |

| Color |

Black |

| Material |

PVC |

| Current |

220 V |

| Number Of Pins |

2 |

| Voltage |

24 V |

| Wire Thickness |

2 mm |

| Current Rating |

3 A |

| Length |

16 Inch |

| Uses |

Transmitting Power And Signals To Every Part Of The Vehicle |

Features of our Wiring Harness

Being one of top wiring harness exporters in India, these all types of wiring

harness are made with multiple types of features inside such as:

- Customizatio

- Durabilit

- Space-Saving Design

- Compliance to Standards

Advanced Applications of our Wiring Harness

A well known wiring harness, our all types of wiring harness

are highly applied and demanded from multiple types of industrial sectors such as:

- Automotive Applications

- Passenger Commercial Vehicles

- Three-Wheelers Specialty Vehicles

- Industrial Equipment

- Home Consumer Appliances

- Medical Devices

- Automotive Industry

- Aerospace

- Home Appliances

- Industrial Machinery

- Medical Equipment

- Telecommunications

- Renewable Energy Systems

- Railway Systems

- Consumer Electronics

- Heavy Equipment and Construction Vehicles

Conclusion:

As a trusted Wiring Harness manufacturers, suppliers, exporters in India, Shreeniwas Equipments Pvt. Ltd offer unmatched quality and reliability for all your wiring needs. By choosing us, you benefit from expertly engineered harnesses designed to ensure maximum safety, durability, and efficient performance across various industries. Our commitment to using premium materials, advanced technology, and stringent quality control guarantees that every wiring harness meets international standards. Additionally, we provide customized solutions tailored to your specific requirements, timely delivery, and excellent customer support, making Shreeniwas Equipments Pvt. Ltd your trusted partner for all wiring harness solutions.

Frequently Asked Questions (FAQs)

-

Q.1 What is the purpose of a wiring harness?

A wiring harness organizes, protects, and routes electrical wires in vehicles and equipment, ensuring efficient transmission of power and signals while simplifying installation and improving safety.

-

Q.2 Who manufactures wiring harnesses for cars?

Wiring harnesses for cars are manufactured by leading automotive component companies such as Shreeniwas Equipments Pvt. Ltd. also produce high-quality automotive wiring harnesses for various vehicle brands including Tata, Mahindra, Maruti Suzuki, Ashok Leyland, and Bajaj.

-

Q.3 Why are wiring harnesses so expensive?

Wiring harnesses are expensive due to their complex design, high-quality materials, labor-intensive manufacturing, testing requirements, and the need for precise customization for different vehicle models.

-

Q.4 What is a wire harness assembly?

A wire harness assembly is the process of bundling wires, terminals, and connectors into a single unit to efficiently transmit electrical power and signals in machines, vehicles, or electronic systems.

-

Q.5 How long does it take to replace a wiring harness?

Replacing a wiring harness can take 4 to 20 hours depending on the complexity of the system, the type of vehicle, and whether it’s a partial or full harness replacement.