As the automotive industry continues to evolve, the shift from traditional internal combustion engine (ICE) vehicles to Electric Vehicles (EVs) has gained tremendous momentum.

One crucial yet often overlooked component in this transition is the automotive wiring harness. Although it may not grab headlines like the batteries or motors, the wiring harness plays a pivotal role in the functioning of any EV.

In this blog, we'll explore what automotive wiring harnesses are, their importance in Electric Vehicles, and why they are an essential element in the future of EV technology.

What is an Automotive Wiring Harness?

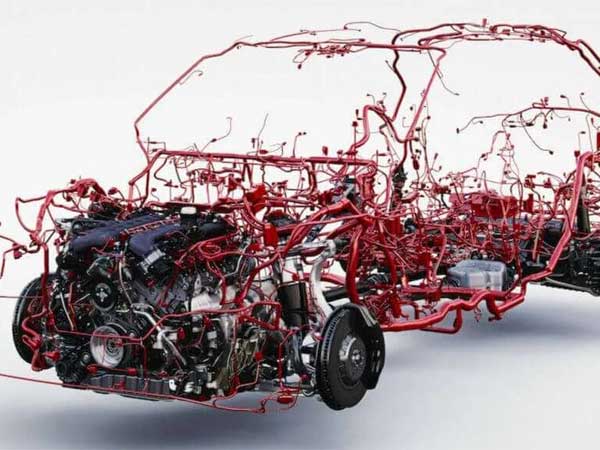

A wiring harness is a complex system of electrical wires, connectors, and terminals that are bundled together to transmit electrical power and signals throughout a vehicle. This essential component ensures the proper functioning of various electrical systems, from lights and power windows to more advanced systems like battery management and regenerative braking. Essentially, the wiring harness serves as the “nervous system” of the vehicle, allowing all electronic components to communicate and operate seamlessly.

Why is a Wiring Harness Important for Electric Vehicles?

Electric Vehicles are equipped with a variety of advanced technologies, many of which rely on electricity for operation. For EVs, the wiring harness is even more critical than in traditional vehicles due to several factors:

1. High Voltage Systems:

Unlike ICE vehicles, EVs run on high-voltage electrical systems powered by large batteries. This requires robust, high-quality wiring harnesses that can safely handle the increased voltage. The design of these harnesses must ensure that the wires can transmit power to the electric motor, battery, and other key systems without risk of overheating or short-circuiting.

2. Battery Management System (BMS):

One of the key components of EVs is the Battery Management System, which ensures the battery is charged efficiently and operates within safe temperature ranges. The wiring harness connects the BMS to the battery pack, electric motor, and other vital components. Without a reliable wiring harness, the entire battery system could fail to operate properly, leading to performance issues or even safety risks.

3. Advanced Safety Features:

EVs come equipped with a range of safety technologies, such as collision sensors, cameras, and stability control systems. These components rely on electrical signals to function correctly, and the wiring harness is responsible for transmitting these signals across the vehicle. A malfunction in the wiring can lead to failure of critical safety systems, which can have serious consequences.

4. Increased Integration:

The growing complexity of modern EVs means that various electrical systems need to be integrated into a compact, efficient design. The wiring harness is tasked with managing a vast network of circuits, sensors, and controllers. As EVs become more sophisticated, wiring harnesses must be designed with flexibility and scalability in mind to accommodate future technological advancements.

Design Considerations for EV Wiring Harnesses

Design Considerations for EV Wiring Harnesses

• Weight:

One of the main challenges in designing EV wiring harnesses is minimizing their weight. Since every extra pound impacts an EV’s overall efficiency and range, manufacturers are focused on using lightweight materials such as aluminum and copper alloys for their wiring harnesses.

• Temperature Resistance:

EVs generate heat, especially around the battery pack and electric motor. Wiring harnesses must be designed to withstand high temperatures to prevent deterioration and ensure safe operation. Insulation materials that can handle extreme heat without breaking down are crucial in EV wiring harnesses.

• Durability and Flexibility:

EV wiring harnesses are often subject to vibrations and movement due to the constant motion of the vehicle. Ensuring that these harnesses are both durable and flexible enough to resist wear and tear over time is vital. Manufacturers also need to consider the environmental conditions (e.g., exposure to moisture, road salt, and UV rays) that may affect the wiring over the vehicle's lifespan.

• Safety Compliance:

As safety is a paramount concern in any automotive design, the wiring harness must meet rigorous safety standards. This includes proper insulation, grounding, and shielding to prevent electrical faults that could pose a risk of fire or electric shock.

Future Trends in Automotive Wiring Harnesses for EVs

As the demand for Electric Vehicles continues to rise, the role of the automotive wiring harness will only become more critical. Here are some trends that are shaping the future of EV wiring harnesses:

1. Smart Wiring Systems:

With the increasing integration of smart technology in EVs, wiring harnesses are evolving to support data transfer alongside power distribution. These “smart” wiring systems can monitor the health of the wiring, detect faults, and even communicate with other vehicle systems to prevent failures before they occur.

2. Autonomous Vehicles

As electric vehicles become increasingly autonomous, the complexity of the wiring harness will increase. Autonomous systems require vast amounts of data to be transmitted across the vehicle, meaning wiring harnesses will need to be capable of handling high-speed data communication in addition to power distribution.

3. Miniaturization:

As EVs become more compact and efficient, manufacturers are striving to reduce the size of wiring harnesses without compromising on performance. This will allow for more room within the vehicle for other critical components, leading to better space utilization and improved design flexibility.

While often taken for granted, the automotive wiring harness is an integral part of Electric Vehicles. With the rise of EVs, the design and performance of wiring harnesses have become more important than ever before. A reliable, high-quality wiring harness is essential for ensuring the safety, efficiency, and overall performance of EVs.

Companies like Shreeniwas Equipments Pvt Ltd. are playing a key role in delivering advanced wiring solutions that meet the evolving demands of the EV industry. As electric vehicles continue to evolve and integrate new technologies, the role of the wiring harness will remain at the forefront of automotive innovation, driving the future of transportation toward a more sustainable and technologically advanced horizon.